Biodegradable PU Coatings for Textiles and Leather

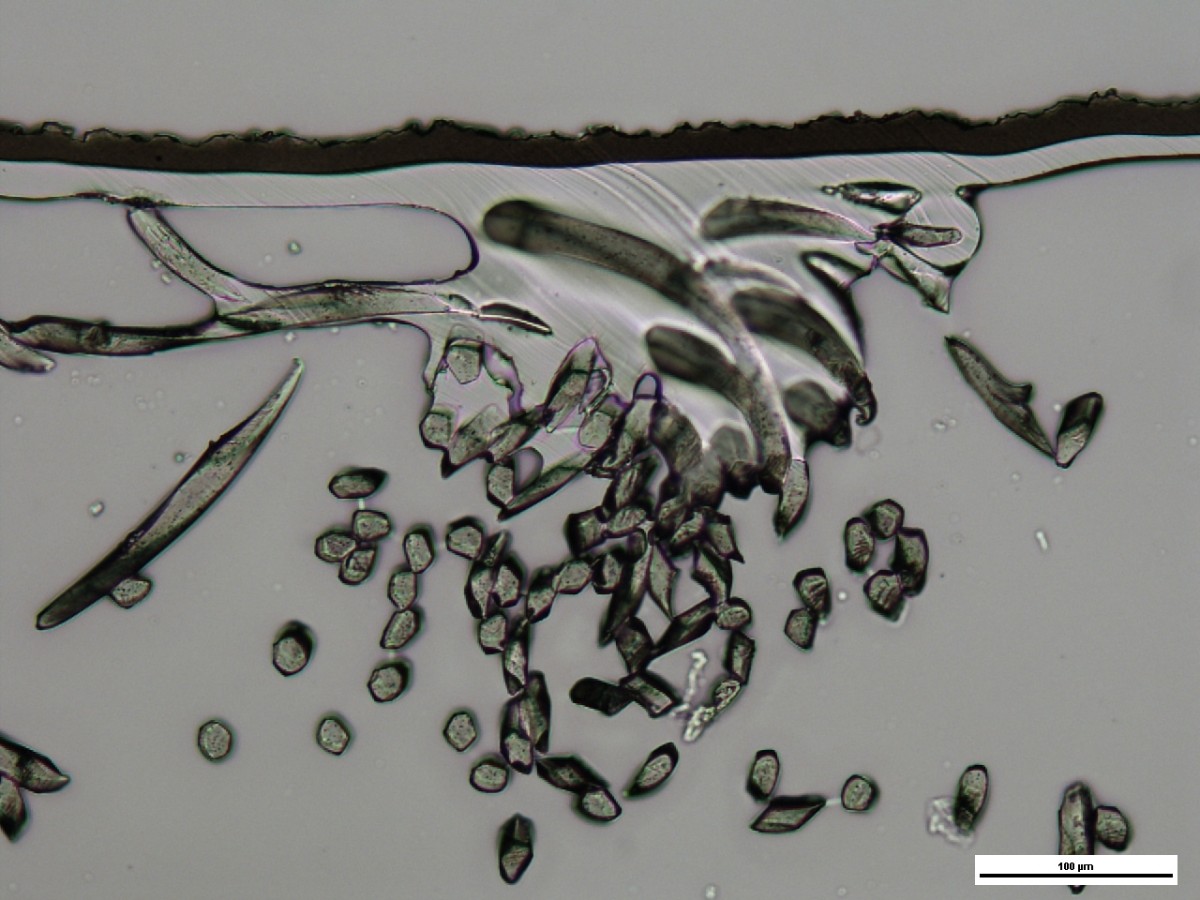

Degradable coatings are desirable in order to increase the biodegradability of coated materials and simplify waste treatment by removing coatings from textiles. De-coated textiles can be recycled according to the type of fabric without impurities from coating polymers.

Challenges for the textile coating industry

When working with PU, companies are facing multiple challenges: they must comply with the REACH regulation and VOC directive, respect exposure limits in the workplace, answer to the requirements set by voluntary labels such as OEKO-TEX® and the ones needed to obtain an environmental licence.

As consumers - being aware of the effects of plastic waste and microplastics on the environment - are increasingly demanding sustainable and green products, companies need to switch to biodegradable materials to answer to the market demand.

Due to the low susceptibility of PU to physical, chemical and biological factors, and the toxicity of some combustion products, landfilling is still the most common way to process PU waste.

Moreover, some changes in the legislation have a major impact.

For example, the revised European Directive 1999/31/EC about landfilling stipulated that after 1 January 2015, only 25% of municipal waste in comparison to the previous year can be deposited in landfills. From 1 January 2030 onward, this will be further limited to 5%.

The development of biodegradable PU will help companies to make the transition to an eco-friendly and sustainable industry giving them a competitive advantage to producers from outside Europe.

Solutions

GUINEA aims to:

- degrade commercial waterborne PU dispersions (PUD) used for textile and leather coating

- develop degradable PUD

- examine the use of enzymes to degrade PU

These coatings will increase the biodegradability of coated leathers, and thus simplify waste treatment and minimize the environmental impact.

Biodegradable textile coatings will minimize pollution during the user phase (avoiding the formation of persistent microplastics by abrasion) and increase the recyclability of coated polyester or polyamide garments, by selectively removing the PU coating through enzymatic degradation.

GUINEA addresses the textile and leather coating industry, the coating related industry such as formulators and the chemical producers. GUINEA focuses on technical textiles and coated leather products.

Project manager

David De Smet

Researcher "Textile Functionalisation & Surface Modification"

dds@centexbel.be

+32 489 871 019

+32 9 241 86 84

Downloads

Project financing

Cornet Project, co-financed by VLAIO

Project HBC.2021.0892

1 August 2022– 31 July 2024