Smart textiles are able to sense and respond to changes in their environment, increasing as such their functionality to the wearer. The main application fields of smart textiles are safety and protection (e.g. technical textiles and workwear), medical support (e.g. monitoring of the elderly) and performance enhancement (e.g. fitness and sport).

Challenges for the smart textile industry

A smart textile product is composed of four elements: sensors, communication paths, a data processor and a power source. The challenge is their integration in textiles.

Unfortunately, the current state-of-the-art solutions do not fully respond to all needs, especially in the field of creating seamless and non-obstructive connections and encapsulations of electronic modules in textiles.

3D printing is an ideal tool to develop alternative strategies to integrate connections & encapsulation in textiles.

Solutions of Smart³D

The Smart³D project aims to fill the gaps (connections & encapsulations) that are presently limiting the integration of electronics in textiles.

A combination of additive manufacturing & novel moulding techniques will be used for prototyping & small production runs.

Aim of Smart³D

The Smart³D project wants to realize smart textile applications by use of 3D printing technologies. This will be done by focusing on three different routes of electric module development:

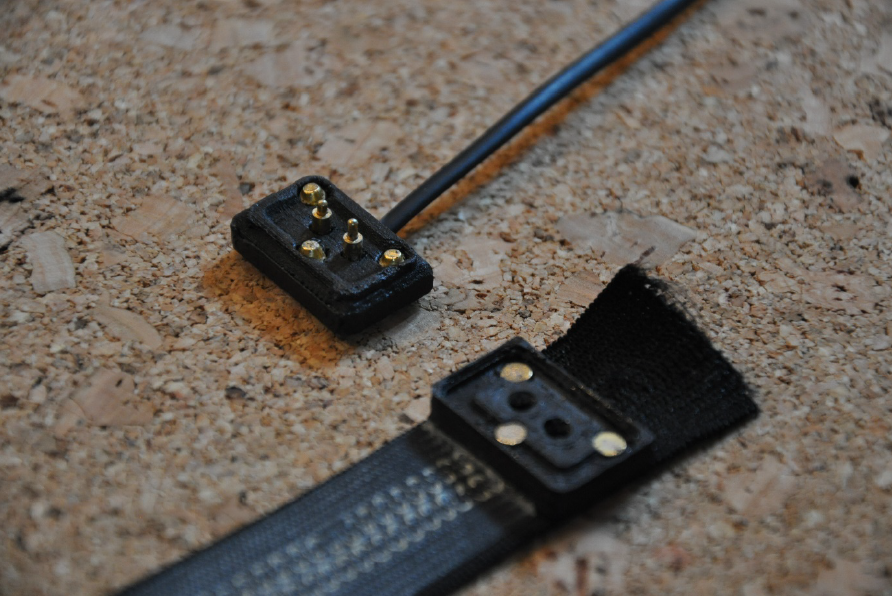

- 3D-printed connector pieces

- conductive paths 3D-printed directly on textile

- 3D-printing of customised moulds for encapsulation of electronic compounds

The project

3D printing is an innovative manufacturing technique that offers the European industry opportunities to create and customize novel, high-value products.

Whereas 3D printing is already an accepted and implemented process in many industries, this is not yet the case in the textile industry, a sector largely composed of SMEs, for which it is very difficult to start up new technologies.

The preceding F³Dprint Cornet project has already made a first step in this direction: customer-specific profiles modeled from scanned data were provided to print 3D applications directly on textiles, resulting in comfort-optimized clothing.

This led to the identification of other high-added value applications for which 3D printing can be a useful technology: the integration of electronic functionalities in clothing, referred to as smart textiles.

Smart textiles are able to sense and respond to changes in their environment, providing the wearer with increased functionality.

The main application fields of smart textiles include safety and protection (e.g. personal protective equipment, PPE), medical assistive devices (e.g. monitoring and assistance for the elderly) and performance enhancing wearables (e.g. fitness and sports).

Basically, a smart textile product exists of four components: sensors, communication paths, a data processor and a power source.

The challenge is to integrate these components into the textile. For many applications the current state-of-the-art solutions do not fully capture all the needs yet.

3D printing can offer an alternative approach to deal with many of the existing challenges.

Demonstrator video

A conductive linear structure, directly 3D-printed onto a fabric with conductive polymer, as an alternative to conductive ink.

Touching the line activates the sensor on the touch board, which produces a sound!

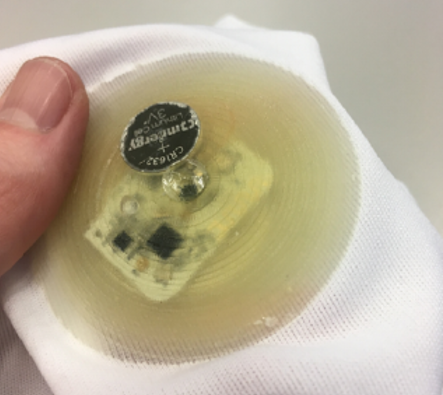

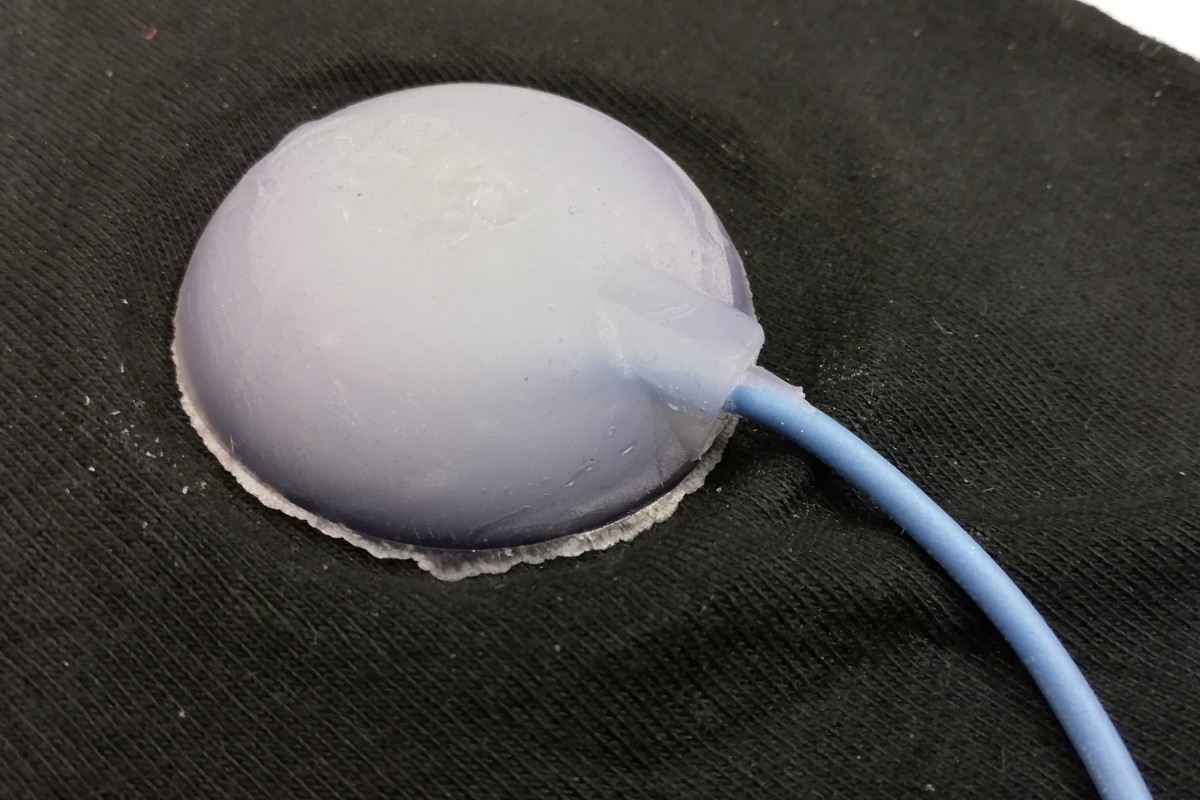

3D-printed encapsulation units

This unit was directly 3D-printed on textile, using two different materials:

- plain TPU

- conductive TPU, functionalized with CNTs

Attaching rigid electronics on flexible textiles?

How did we succeed in squaring the circle?

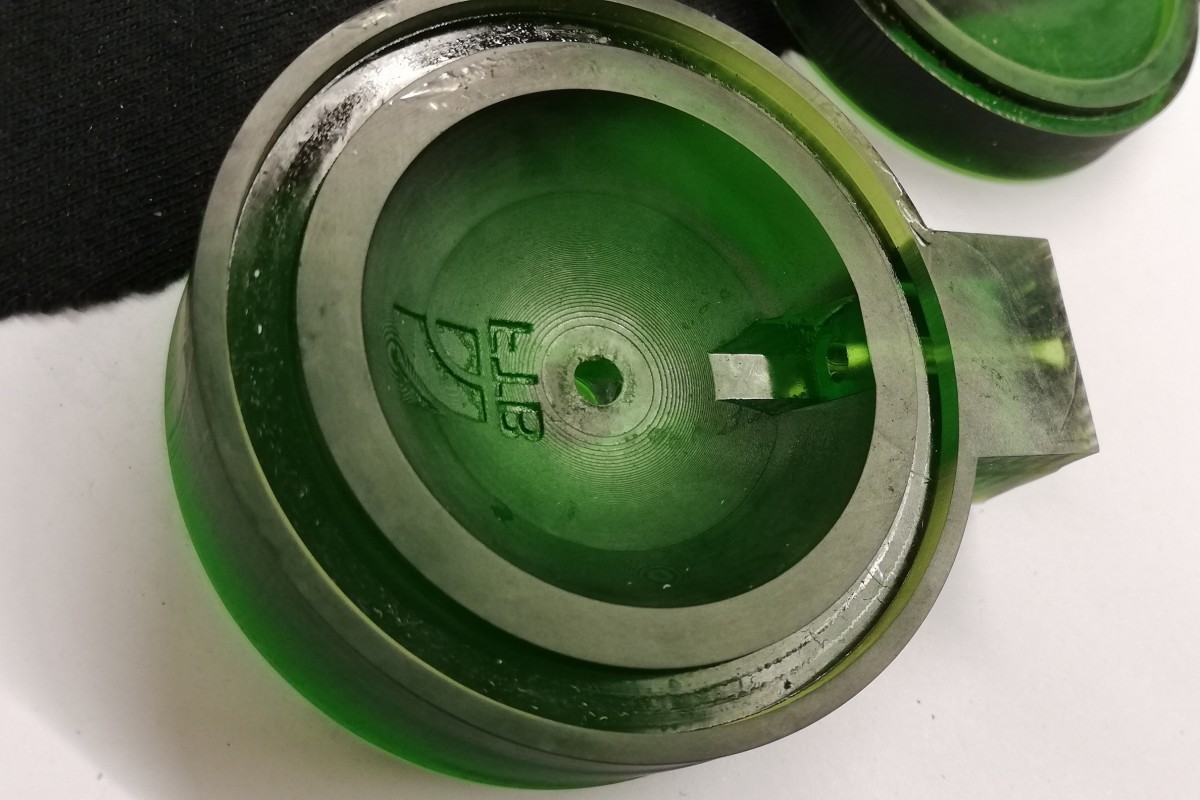

Centexbel-VKC and the smart³D project partners are developing a novel method based on low-pressure molding to secure electronics, wires, and cables in a secure and watertight manner onto textiles.

Step by step we are creating integrated electonic textiles!

To this end, we designed and printed molds by means of additive manufacturing techniques. We used specific grades of hotmelt resins or 2K polyurethanes to encapsulate or pot the electronics.

Project managers

Research partners:

HOCHSCHULE NIEDERRHEIN – RESEARCH INSTITUTE FOR TEXTILE AND CLOTHING (FTB)

Dr. Michael Korger

Alexandra Glogowsky

Dr. Jens Meyer

FORSCHUNGSKURATORIUM TEXTIL

Project financing

Cornet project, cofinanced by Vlaio

Project no. HBC.2019.2673

The project started July 1st, 2020 and ended on June 30th, 2022